One of the best ways to prevent pest activity is to incorporate exclusion in your pest management program

Pest proofing not only prevents pests from entering a building but can also prevent interior pest movement. In addition to restricting movement, exclusion can reduce the areas where pests can harbor and food sources can accumulate. It provides long term control and reduces the need for pesticides. Some accreditation programs like LEED and the National Organic Program, will specify non-chemical efforts as the first step in pest remediation. Exclusion can satisfy the need for non-chemical strategies.

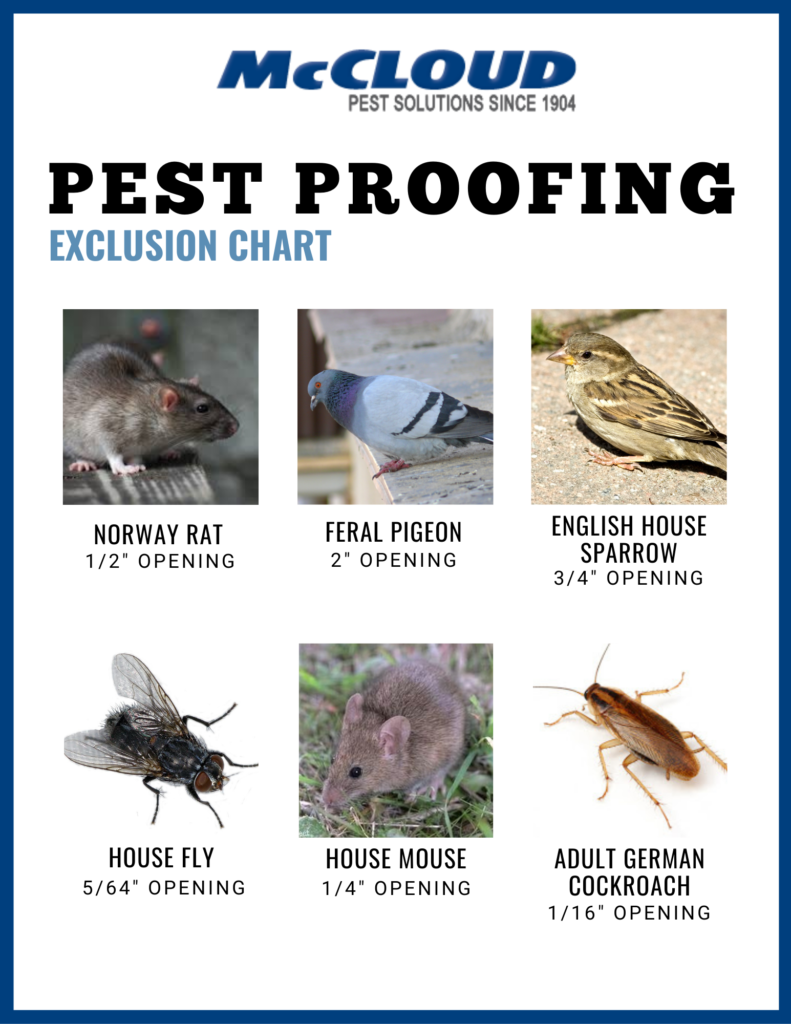

The smaller the pest, the greater the degree of sealing or pest exclusion required. Pests have an amazing capability of fitting into and through small cracks and crevices. The chart to the right shows some of the common pests and the size opening that they can squeeze through in entering or moving through a structure. When targeting these pests, you want to exclude to a level smaller than the opening size listed.

Pest Proofing Materials

Many of the materials used for pest proofing can be found at the common hardware supply store such as screens, sealants and door brushes. There a few items that doors are specially designed for the pest management industry with pest prevention in mind. Included in this list are the Xcluder stainless steel mesh products. For food facilities, sealants should be selected which are designed for the surface being sealed, size of opening to be sealed, and with food grade ratings. Sealers, sealants and caulks are used for different types of cracks and surfaces.

Sometimes it is not a material but a timing mechanism that must be adjusted. Doors need to be in good repair and that good repair extends to the timing mechanisms of the doors. Automatic openers should be adjusted such that they remain open long enough for the pedestrian to move safely indoors but not longer than necessary to allow pest entry. Six seconds is a commonly used time frame for doors to remain open past the time the person entering or exiting passes the electronic door sensor. If there are automatic doors at the facility, periodically check the doors for proper open and closure. Some pests such as birds have learned how to trigger automatic doors to permit entry by the pest. Adjustments to the sensitivity of the sensors may be needed to avoid this issue.

If a door needs to remain open for ventilation purposes, screens should be used to prevent pest entry. Overhead dock door screens are available from a variety of manufacturers. Screens that fit on the door track are preferred.

As indicated below, doors should be sufficiently tight enough to seal out most insects and rodent pests. You can use a pencil as a tool to determine if a mouse sized rodent can enter through a door opening. If openings are present to permit entry, additional door seals are required. Do not overlook dock door plates and seals around these areas in addition to the door itself. Door sprags can be used to help seal the area where the door meets the dock plate.

- Sealer (Liquid Coatings): Used to seal hairline cracks or pores on a surface.

- Sealant: Used for cracks where movement is expected.

- Caulk: Small joints which are 1/4″ or less in size where little to no movement of the joint is expected.

Layers of Defense

Lastly, just like in any security program, having layers of defense can be helpful in preventing problems. Vestibules with an inner and outer door can be helpful as a second line of defense in keeping pests out. Quick or rapid roll up doors can also be beneficial in separating sensitive areas like food packaging and processing from less sensitive areas with may have greater pest exposure like receiving docks. Consider those layers of defense in construction and remodeling of facilities. The multi-layered approach can be especially helpful in situations where pest population pressures are heavy, there are negative pressure issues in the building or product sensitivity is extremely high.